YN-B704 Pre-laid Waterproof Membrane

DETAIL

YN-B704 Pre-laid Waterproof Membrane

Product Introduction

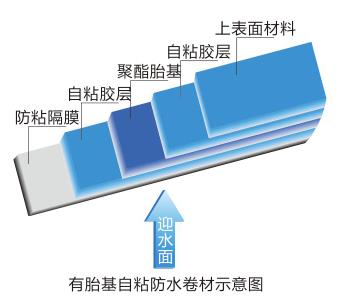

YN-B704 Pre-laid Waterproof Membrane is made of self-adhesive polymer modified asphalt as the base material, with polyester reinforcement layer, covered with a polyethylene film (PE film) or a peelable silicone-coated release film on the lower surface, and a peelable silicone-coated release film or a reduced-adhesion protective layer on the upper surface. It is an asphalt-based polyester reinforcement waterproof membrane that can be pre-laid and applied with adhesion construction.

Product Features:

- It can be bonded with the subsequently poured concrete as a whole, remaining inseparable even after long-term immersion in groundwater.

- It can be applied on wet or even uneven surfaces without the need for a primer. During construction in the rainy season, its advantages are even more prominent, making it a powerful measure to ensure the construction schedule.

- The use of solvents and fuels is eliminated during the construction process, reducing environmental pollution and safety hazards, and conserving resources.

Precautions:

- Do not use metal or hard objects to damage the roll material.

- After completion of construction, when reinforcing steel bars or pouring concrete, the waterproof layer should be protected.

- Do not apply the roll material on a contaminated, waterlogged, or icy base surface.

- The construction process should be carried out step by step, without any cross-construction.

Scope of Application

It is suitable for waterproofing projects of the base plates and side walls without construction space in engineering such as buildings and open-cut subway construction.

Construction Process/Procedure

Pre-laying Method:

Base cleaning → Laying reinforcement layer → Roll positioning → Laying large-area rolls with self-adhesive surface facing the structure in an empty manner → Reinforcing and sealing nodes → Quality inspection and acceptance → Tearing off the upper surface release paper (film) → Binding reinforcement bars → Repairing rolls → Pouring structural concrete.

Storage and Transportation

- Rolls should be stored in a dry, ventilated environment to prevent sun exposure, rain, and moisture.

- Rolls of different types and specifications should be stacked separately and should be laid flat.

- Rolls should be transported in an upright position, without tilting or cross-stacking.

- Under normal conditions, the storage period is one year from the date of production.

Specification and Model

Thickness: 4.0mm; Length: 7.5m

Technical Specifications/Technical Parameters

Execution Standard: GB/T 23457-2017 (PY Category)

REVIEW